HYDRAULIC FRACTURING (FRACKING)

February 23, 2013

In writing this blog, I have used the following sources: 1.) www.chevron.com, 2.) www.conocophillps.com and 3.) www.propublica.

We have heard a great deal about the pros and cons of hydraulic fracturing or fracking over the past few months. The purpose of this posting is not to debate those good and bad points but to merely deliver my understanding of the process. You decide.

OK, just what is hydraulic fracturing? By definition: Hydraulic fracturing is a process used in nine out of 10 natural gas wells in the United States, where millions of gallons of water, sand and chemicals are pumped underground to break apart the rock and release the gas. Once the rock is fractured, natural gas, or more appropriately methane, is released, piped upward, captured in containment vessels and transported to stations where it is generally compressed; i.e. CNG or compressed natural gas.

Natural gas is an efficient energy source and the cleanest-burning fossil fuel producing lower levels of greenhouse gas emissions relative to the heavier hydrocarbon fuels such as coal and oil. Its heating value is approximately 1200 Btu/Ft.³ which makes it a viable candidate for many combustion processes. Natural gas resources developed from shale rock have resulted in lower-priced natural gas for U.S. consumers, making it less expensive for Americans to heat their homes and generate electricity.

Although the energy industry has long known about huge gas resources trapped in shale rock formations in the United States, it is over the past decade that energy companies have combined two established technologies—hydraulic fracturing and horizontal drilling—to successfully unlock this resource.

The U.S. Energy Information Administration (EIA) estimates the United States possesses more than 2,500 trillion cubic feet of technically recoverable natural gas resources, of which 33 percent is held in shale rock formations. Natural gas from shale has grown to 25 percent of U.S. gas production in just a decade and will be 50 percent by 2035, according to the EIA. Developing this resource can help enhance energy security and strengthen economies.

Natural gas from shale rock is providing the United States with reliable, affordable, cleaner and responsibly produced energy. Developing these natural gas resources can help enhance the country’s energy security, strengthen local and state economies, and fuel job growth. In 2010, the development of the Marcellus Shale, in Pennsylvania, alone generated $11.2 billion in the regional equivalent of gross domestic product, contributed $1.1 billion in state and local tax revenues, and supported nearly 140,000 jobs. The predicted growth of the resource likely means we also can expect to see correlating economic and energy security benefits over the coming years.

Before drilling a well, our geologists and engineers complete a full analysis of the geology using proprietary and public data. They assess results from other wells drilled in the vicinity, including water wells, producing oil and gas wells and non-producing wells (dry wells). A plan is developed for drilling and completing the well that must be approved by state regulators. The company proactively engages key stakeholders, including communities, officials, government agencies and regulators, as plans are being developed.

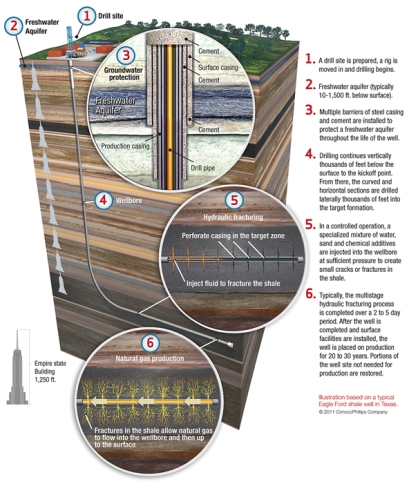

Many of the steps described are common to all oil and gas well planning and operation efforts, regardless of well design or the formation being targeted for development. In describing how this process is brought about, we will use the following pictorial as a reference:

- Once a target formation has been identified and appropriate land leases acquired, environmental and regulatory reviews are conducted to assess related environmental impacts. Social and local issues are addressed, and stakeholder engagement commences. The permitting process then begins as prescribed by federal, state and local regulatory requirements.

- Before drilling begins engineers, geoscientists and environmental employees work with regulatory staffs to collect and analyze information on the geology and surface conditions of the potential drill site. Drilling, surface use and water management plans are developed to maximize natural gas production while protecting the environment and minimizing the well’s overall footprint.

- Following the construction of a well pad, a large hole is drilled to a shallow depth. A relatively short length (typically 40 to 120 feet) of large-diameter steel pipe (conductor casing) is set to stabilize the ground at the top of the well.

- Drilling continues to a pre-determined depth below the base of usable water. This depth is specified by state or federal regulators for the purpose of protecting potential usable groundwater resources and is based on local geology. While drilling this section, drilling mud – a mixture of fresh water and clay – is pumped into the hole to cool the drill bit, remove any cuttings and create a boundary between the well and surrounding rock.

- The drill pipe and drill bit are removed, and a steel casing is inserted. Cement is pumped through the casing, filling the annular space between the outside of the casing and the well bore. This creates a sealed container that extends from the surface to below the base of freshwater zones. The blowout preventer is then installed at the surface.

- Following a series of tests, drilling resumes until it reaches the kick-off point – when a specialized motor is added to the drilling assembly that allows the curved and horizontal sections of the well to be drilled. The kick-off point is typically thousands of feet below any freshwater zones.

- Once the target depth is reached (based on the length of the horizontal section required), the drilling assembly is removed, and the steel casing is inserted through the entire length of the well. More cement is pumped through the casing, creating another cement-reinforced layer of protection.

- Next, a specified length of horizontal casing is perforated to provide a way for natural gas to enter the production casing.

- A fluid consisting of water, sand and a small amount of chemicals – some of which can be found in common household and food products – is then injected through the perforations to stimulate gas recovery. The fluid penetrates the shale and creates cracks, or fractures, in the rock. The sand or ceramic particles, called proppant, are carried by the fluid and deposited in the narrow fractures, creating a pathway for gas to reach the well. This step is called hydraulic fracturing.

- A plug is set inside the casing to isolate the stimulated section of the well. The entire perforate-inject-plug cycle is then repeated at regular intervals along the horizontal section of the well. Finally, the plugs are drilled out, allowing the gas and fluids to flow into the well bore and then up to the surface inside the casing or tubing.

- The gas/fluid mixture is separated at the surface, and the fracturing fluid (also known as flowback water) is captured in steel tanks or lined pits. The fracturing fluids are then disposed of via government-approved methods.

- The entire well construction process generally takes only two to three months, compared to the 20- to 30-year productive life of a typical well.

I certainly hope this brief write-up is helpful to you in understanding the process. I will make every effort to continue following this technology and report as needed. Any comments will be greatly appreciated.

July 9, 2013 at 23:00

Alright so after having this account for sometime I have finally made my first post. I have been a fan of these forums for years but just lurked and read through threads.

LikeLike

January 7, 2014 at 19:01

Hello William–I enjoy writing and posting although it’s tough work for me. I’m not a natural when it comes to putting words together. I do love the research though. Thanks for taking a look and please do come again. Take care.

LikeLike

July 4, 2013 at 10:12

Weird , your posting shows up with a black hue to it, what shade is the primary color on your site?

LikeLike

July 6, 2013 at 13:02

Andrew–The primary color for the background is jet black. The font color is definitely white. I chose these colors due to contrast. Many thanks for taking a look.

LikeLike

July 3, 2013 at 12:32

grande post. è molto utile per le persone. vi dirò altro mio amico a visitare il sito per non aiutare. grazie per il bell’articolo.

LikeLike

July 6, 2013 at 13:15

Thank you so much Waldo. Really appreciate you taking a look and please do come again.

LikeLike

June 18, 2013 at 06:26

You did the a great work writing and revealing the hidden beneficial features of

LikeLike

June 19, 2013 at 18:01

Hello Eli Illar. I was beginning to wonder if anyone was looking at Fracturing. It’s a bit technical but I feel very interesting. Certainly am happy you dropped by to take a look. Please come again.

LikeLike

June 14, 2013 at 22:39

I personally feel that this one is the best work from you.

LikeLike

June 19, 2013 at 18:09

Hello Vitamins–Thank you so much. It’s always good to here someone feels you are doing a good job. I really try to provide value-added to my readers. Please come again.

LikeLike