INDUSTRIAL SAFETY

March 18, 2014

In 1986 I joined a Fortune 100 company as a product design engineer. The company had an extensive safety program which included a three -day course with first aid and bio-hazard training. The instructur made one introductory comment I will never forget.

“I don’t care if your time with us is five minutes or fifty years. We want you safe while on your way to work, while you are here and then during your commute home”.

This statement, or some version of this statement, has probably been made thousands of times– with feeling. No one wants injuries to occur whatever the environment and certainly not a workplace injury. It is absolutely imperative employees perform their functions under safe conditions. With that being said, the employee must realize accomplishment of this goal means he or she must meet the company half way. Provisions for a safe working environment are a team effort. OSHA (Occupational Safety and Health Administration) has specific guidelines relative to safe working conditions companies and individuals need to follow to avoid injury. Each state has adopted guidelines to govern working conditions. These may be more stringent than OSHA but generally, they fall along the same guidelines hoping to produce the same results.

Employers that invest in workplace safety and health related activities can expect to reduce fatalities, injuries, and illnesses. This will result in cost savings in a variety of areas, such as lowering workers’ compensation costs and medical expenses, avoiding OSHA penalties, and reducing costs to train replacement employees and conduct accident investigations. In addition, employers often find that changes made to improve workplace safety and health can result in significant improvements to their organization’s productivity and financial performance. If an employee knows the company he or she works for is involved with providing a safe working environment on a day to day basis, that employee will work with less tension and less fatigue at the end of the day. With this in mind, let us take a look at several rules that may govern workplace safety.

The following safety rules are admittedly somewhat “generic” but definitely apply to commercial concerns working to insure safety of personnel in the physical facility and in areas such as parking lots and out buildings. It is imperative that companies examine and develop their safety methodology depending upon need. This list might be a very good place to consider and begin.

- Report all incidents or injuries immediately to your supervisor or lead coordinator. Failure to report may result in additional medical problems that could have been prevented. Never “work through” an injury. Never “push on” thinking the condition will get better as time goes by. Seek medical attention immediately to forestall additional difficulties.

- Be alert at all times and never take shortcuts that conflict with safe procedures. When in doubt, seek advice from supervisory personnel or lead coordinator.

- Safety devices, such as interlocks and machine guards are not to be removed or made inoperative unless under the control of safe maintenance practices and lockout/tagout procedures are being utilized.

- Report defective machinery, equipment or unsafe conditions immediately to your supervisor or lead coordinator. It is recommended that a written, as well as verbal, communication be used when discussing the problem.

- Safety procedures and personal protective equipment (PPE) must be utilized as specified by the safety committee or safety coordinator. All necessary PPE; I e., gloves, safety glasses, steel-toed boots, hard hats, hearing protection, respirators, wrist bands, protective sleeves, waist belts,etc. must be worn at all times and never removed when in the work cell.

- Make sure you are dressed appropriately for the environment you are working in. In most industrial facilities, wearing short pants, open-toed shoes, sandals, high heels, loose or baggy clothing, tank tops, halter tops, etc is prohibited.

- Long hair extending beyond shoulder level can be very hazardous when operating moving machinery. It must be pulled back. (Use common sense.)

- Use proper lifting techniques. Consider the load, keep your back straight and use your legs for lifting. Seek help if the load is too heavy. Don’t do the macho-man thing and assume you can lift a load over forty (40) pounds. Anything over forty (40) pounds requires assistance.

- Good housekeeping practices are a must in an industrial environment. Keep your work area clean and free from clutter. Keep all aisles clear and all items stored properly in specified locations. Be aware of boxes and components protruding into work areas and remove as needed.

- Walk—do NOT run in the facility or on facility grounds.

- Horseplay is definitely never condoned and practical jokes may cause injury to you or your co-workers. DON’T DO IT.

- Always be aware of overhead work such as cranes and conveyor equipment performing overhead work. Make sure you are not directly under an elevated conveyor system carrying parts through the facility. (NOTE: Industrial engineering departments and personnel must NEVER position a pedestrian walkway directly under an overhead conveyor.)

- If you are operating an overhead crane, always use a fall-protection device such as a safety belt or guard rail.

- Seatbelts MUST be worn while operating forklifts. Operators must drive at safe speeds and sound their horns when approaching ALL intersections. All forklift rules must be followed implicitly. NEVER DRIVE WITH FORKS ELEVATED.

- Compressed air must never be used to clean dust from your clothing. Hand-actuated air nozzles must not exceed the OSHA thirty (30) PSI maximum pressure rating.

- Safety glasses or safety goggles combined with face shields MUST be worn while using pedestal bench grinders, portable grinders, reciprocating saws, skill or circular saws and jig saws. Appropriate gloves must also be worn.

- Follow all plant security procedures while entering and exiting the facility. Keep your personal belongings stored and secured in a way that does not invite theft.

- Be committed to safety by creating a workplace free of recognized hazards. Work as a team to improve safety and reduce “at risk” behavior.

- NEVER “ride” a conveyor, static or moving. Use the appropriate “step-overs” when moving from side to side.

- In many facilities robotic systems are used for processes. Always be aware of equipment movements and the path those movements may take. If safety barriers around robotic systems become inoperable, report this to your supervisor and DO NOT OPERATE until the condition is fixed.

- Do not allow extension cords to lie on floors where abrasion and tearing can occur. Equipment should be hard-wired where insulated wiring runs through conduit. Temporary wiring should be located above floor level and never placed on the floor. Call your supervisor when problems of this nature arise.

- Anytime ladders are needed they must be in good repair AND non-skid feet firmly placed against flooring. Never use a ladder on a sloping surface. Never use a ladder to reach excessive heights. Scissor lift or “cherry-pickers” are much preferred.

It is imperative that any vendor or contractor be advised of safety rules within your facility. They must abide by the very same rules you adopt for safety. THIS IS A MUST.

I certainly hope you benefit from this very brief write-up and would enjoy your comments.

ENERGY-SAVING IDEAS FOR RESIDENTIAL DWELLINGS

March 8, 2014

This past winter our family experienced a power outage due to ice-laden tree limbs falling on power lines. The Electric Power Board truck came roaring into our driveway one afternoon to make the necessary repairs. The cherry-picker had the technician in the air in no time. The work was completed in about an hour. I brought both techs a cup of coffee and started a conversation regarding the capacity of the transformer hanging in my backyard. I was very surprised to find the device, supplying five (5) houses was running at 250% capacity. This was approximate, but close enough. We have lived in our home for thirty-eight (38) years but apparently the devices needing voltage supplies have increased tremendously. I was told computers, charging mobile phones, stereo equipment, home entertainment centers, microwave ovens, etc have added greatly to electrical demands.

Given below are five of the best energy-saving gadgets you can implement within your home. From kettles to phone chargers, these devices endeavor to reduce your energy usage and provide you with an array of easy-to-use, innovative household amenities.

NEST:

Nest has engineered an easy-to-install, energy-saving home thermostat. This device interrogates your daily routine and automatically adapts its settings to suit your heating preferences throughout the day. All you have to do is alter the thermostat to your particular needs, and the Nest will develop a personalized heating schedule. You can alter this schedule at any time should your preferences change. What’s more, a special Leaf feature informs you of the most energy-efficient temperatures for your home. A handy Auto-Away option ensures that your heating is turned off when you leave. Irrespective of your living arrangements, the Nest is a thermostat that adapts to your every need. It saves you energy while offering you optimum heating comfort. The device sells for about $249.00 and takes about one week to “learn” the comforts you wish. It also has a remote control device.

BELKIN CONSERVE VALET:

If you always leave your phone charger plugged in, this ingenious gadget is for you. The Belkin Conserve Valet enables you to charge four devices at the same time. Moreover, when charging is complete, the device cuts the power completely, thereby saving you from expending unnecessary energy on a plugged-in charger. It also monitors the power gauges of your devices to ensure they are always fully charged via the most environmentally economical method available. Most chargers continue to use power as long as they’re plugged into the wall—even after you unplug your device. The Conserve Valet Smart USB Charging Station lets you charge all of your mobile devices in one convenient place, and automatically shuts off power—including standby power—after devices are fully charged. It even senses when new devices are added so you always get a full charge, and has an innovative cord management system to keep things neat. Keep your devices ready to go, and save energy, too. This device is priced at $99.98 through Amazon.

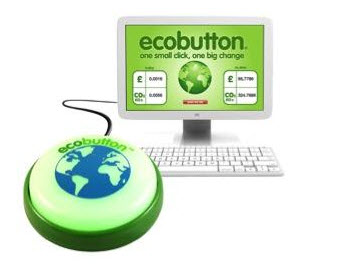

ECOBUTTON:

The Ecobutton is an ideal gadget if you want your PC to use less power. You simply press the Ecobutton when you’re away from the PC, and the device places the computer into its most efficient energy-saving mode. Furthermore, it will record how much power, money, and carbon units you’ve saved using it. The data it provides is beneficial in enabling users to monitor, and therefore reduce, the power use of various computers. The cost is only $8.00 UDS and is definitely well worth the price.

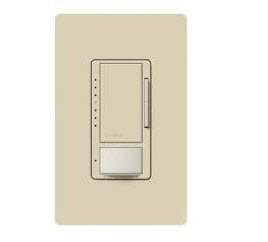

MAESTRO OCCUPANCY/VACANCY SENSOR:

Always forgetting to turn off your lights? The Maestro Occupancy/Vacancy Sensor senses when you enter or exit a room and switches the lights on or off accordingly. This device automatically turn lights on when you enter a space and off when you leave, creating a convenient way to save energy at home or commercial space. They’re ideal for rooms where lights are accidentally left on, such as an office, or rooms that you often enter with your hands full, such as a laundry room or supply closet.

A sensor detects the amount of natural light in each room and adjusts the lighting to reach your preferred level. This device effortlessly provides you with efficient lighting throughout your home, illuminating with energy-saving ambience.

Consult your local hardware store for pricing.

ECO KETTLE:

Highly recommended by the Energy Saving Trust, the easy-to-use Eco Kettle can reduce your tea-related energy expenditures by 30%. It lets you select exactly how much water to boil. It also contains a handy reservoir, so you don’t have to top up your kettle every time you make a fresh pot of tea. With prices starting at just £20 ($33), an Eco Kettle can drastically reduce your water use. A top-of-the-line model is about $63.00 US. The built-in measuring capacity of the Eco-kettle adds convenience and precision. We should hope that the design also provides for an automatic shut off when the water reaches boiling point, and insulation to keep water hot until that phone call is finished. Bundling features is an advantage if it leads to a personal enjoyment that encourages conservation…to a point that is price determined.

As we all know, there are probably many other energy-saving ideas and processes. The ones I have mentioned above are moderately priced and used in the home. Hope you enjoy the write-up.

ENTITLEMENTS

March 5, 2014

Unless you are new to my postings, you know that I rarely (very rarely) do politics. I think politicians are fascinating only because I think all people are fascinating. Culture, background, ethnicity, language, etc. all intertwine to produce a mosaic that essentially defines who we are individual. We are one of a kind. There is no one like us. I also think the act of being political is a huge impediment to progress. One example, Congress. In my lifetime, I can never remember such a contentious and mean-spirited group of losers. The “us versus them” mentality is alive and well. If I hear the word “brand” one more time or the phrase “appealing to my base”, I think I just might scream. Adding to my disgust was the following cartoon in this Sunday’s paper. It really hit a sour note; a very sour note indeed.

The sargent on the left is the emodiment of the entitlement mentality. The little guy on the right is the United States military. The entire article addresses cuts in spending for the DOD, specifically the reduction in benefits to men and women who serve in uniform.

Merriam-Webster defines entitlements as follows:

- Noun—“The condition of having a right to have, do, or get something”

- “The feeling or belief that you deserve to be given something, such as a special favor”.

- “A type of financial help provided by the government for members of a particular group.”

The Declaration of Independence, signed July 4, 1776, addresses our unalienable rights and states these rights are life, liberty and the pursuit of happiness. This marvelous document in no way indicates we are entitled to anything over and above these three rights. In looking at the first ten (10) admentments to the Constitution, we are guaranteed the following: 1.) Freedom of Religion, 2.) Freedom of Speech, 3.) A Free Press, 4.) Freedom to Assemble, 5.) The Right to Keep and Bear Arms, 6.) Freedom for Unreasonable Search and Seizure, 7.) Security in Personal Effects, 8.) Freedom from Warrants Issued Without Probable Cause, 9.) Indictment by a Grand Jury for any Capital or “Infamous Crime” and 10.) Guarantee of a Speedy, Public Trial with an Impartial Jury; and Prohibition of Double Jeopardy. These first ten admentments are called the Bill of Rights. Please note: nowhere in the Bill of Rights are we guarenteed “free stuff”. It was assumed by the creators of the document that the average individual would accomplish in accordance with his or her abilities and would strive for personal improvement in the process. Allowances such as Social Security, Medicare and Medicaid, in my opinion, do not fall under the term entitlements. These services have not been free. They are paid for by withholding from income. This is how we pay for these benefits. Free mobile phones, food stamps, subsidized housing and many others were not comtenplated by our founding fathers. I feel certain they would be rolling over in their graves if they had an inkling as to where we are in this country. Please don’t get me wrong, there are those individuals who need help from their federal government from time to time BUT cutting benefits for our military is JUST WRONG when these cuts are done to provide additional entitlements. OK, reduce “head count”. Shrink the force. Cancell or mothball weapon systems but don’t alter benefits. Don’t freeze pay grades. Don’t cut commisary access. Don’t reduce insurance. Don’t raise the grocery bill for the uniformed military. Don’t alter training due to cutbacks in spending. Having been in the Air Force for four years, I can tell you it is not always a picnic. The monthly income is not why we serve. This can be borne out by the fact that a great many uniformed personnel are using food stamps. I worked on ICBMs carrying nuclear pay loads. No one at me and times were still tough due to very low comparable wages and long hours. In my opinion, the uniformed military deserves decent pay for services rendered and some assurance benefits will be available at retirement. The world remains a very dangerous place. The United States will continue to engage, and that takes a strong, well-trained, optomistic uniformed military.

CARBON MONOXIDE AND DEATH

March 1, 2014

Over the past three or four weeks we have been advised of several tragedies resulting from carbon monoxide poisoning. Due to the ridiculously cold winter we have experienced this year heating systems have been running just about non-stop. I have several friends in the northern part of our country that have heating bills topping the $700 per month level. Gas-fired heating systems MUST operate properly or death can occur as a result of an over-abundance of carbon monoxide in the products of combustion. This, unfortunately, has happened all too frequently this winter. Let’s take a very quick look at how this can occur, and why proper maintenance of heating systems is absolutely critical.

CARBON MONOXIDE.

Carbon monoxide (CO) is a colorless and odorless gas that is decidedly poisonous. CO is NOT found in natural gas but is generally the product of incomplete combustion. The presence of carbon monoxide in the products of combustion has an important relationship to combustion efficiency. CO (2) is a measure of complete combustion whereas CO is a measure of incomplete combustion. The American Gas Association (now the Canadian Gas Association) says a maximum of 800 parts per million (PPM) for CO (carbon monoxide) must not be exceeded for safe operation. In the United States, the two most-used gases are natural (primarily methane) and liquefied petroleum (LP). Every gas-fired burner must exhibit CO levels below 800 PPM for acceptability. The effects of carbon monoxide may be seen from the following chart:

You can now see why the 800 PPM is considered to be the very maximum level of CO in products of combustion. CO can be a very DEADLY constituent resulting from incomplete combustion.

In looking at atmospheric gas burners, we note that two (2) sources of air are available; i.e. 1.) Primary and 2.) Secondary.

PRIMARY AIR:

Air which is mixed with gas before that gas/air mixture is ejected and ignited at the ports is called primary air. A definite minimum amount of primary air is required for complete combustion no matter what gas type is being used. That minimum percentage of primary will vary depending upon the type of gas, its specific gravity and its heating value.

SECONDARY AIR:

All other air supplied to the burner is called secondary air. In an ideal case, primary air and secondary air should be 100% of the air needed for complete combustion. All air supplied is called total air.

Ideally, 10 cubic feet of air is needed for 1 cubic foot of natural gas if complete combustion is to be accomplished. Suppose that 15 cubic feet of air is supplied to a burner for each cubic foot of gas. The total air is 150% (15/10 X 100%). Excess air is 50% (150%-100%). Now suppose that 5% of the air supplied from that 15% is primary air. The remaining 10 cubic feet would be secondary air and excess air.

Approximately 20 cubic feet of air is needed for 1 cubic foot of propane and 30 cubic feet of air is needed for butane. Please note that this is a volumetric measurement with the respective flow rates being in FT³/ Hr. It is proper to consider Ft.³/Hr of fuel gas combined with Ft.³/Hr of primary air for complete combustion. This mass flow rate would be the total mass flow rate for the mixture of gas and air entering the mixing tube.

Ideal burner characteristics may be noted as follows:

IDEAL BURNER CHARACTERISTICS:

- Blue flame with possibly some yellow tips when using propane or butane as the fuel. ( NOTE: These burners are firing natural gas with a heating value of approximately 1075 Btu/Ft³ )

- Distinct individual flame pattern. You can count the number of ports by counting the number of individual flames emanating from those ports.

- No blowing or lifting of flames; i.e., separation of the flame from the burner port.

- No lazy flames. (This is an indication of too little primary or secondary air.)

- No flash-back of burner flames.

- No offensive noise during ignition, operation or extinction.

- No offensive odors emanating from the combustion process.

- Flame heights are uniform around the burner periphery. (NOTE: In looking at the simmer burners below (smaller burners), you will notice that the flame heights are not equal. This is by design and involves the configuration of the burner grates mounted above the burners themselves. )

The burners above show flame patterns producing complete combustion with minimal CO in the products of combustion.

POOR BURNER OPERATION:

Now, I would like to show you a picture of a burner system that is NOT firing properly. Sometimes it is easier to discuss proper operation by looking at a burner behaving badly. This design, shown below, breaks ALLof the rules given above. This is a gas grill basically used for “tail-gate” cooking. The propane tank and grill are integral parts of the trailer. The trailer is attached to the car with a bumper hitch, and then towed to the game behind the vehicle. I was asked to “pass judgment” on the design and indicate to the designer what corrective actions I would recommend. It did take some time.

Here is what we know:

- Yellow flames; an indication of inadequate primary air and incomplete combustion. This condition will produce sooting (or carboning) and will generate an intolerable amount of carbon monoxide. If this product were used in an enclosed space, there would be definite issues with the accumulation of carbon monoxide. We can expect some yellow tipping because the fuel gas is propane. Typically, propane and butane produce yellow burner tips but this is much too much and represents a condition that must be rectified.

- Flame height is very irregular which tells me there are real issues with primary air injection, burner alignment and issues with the burners being level relative to the mounting system. The orifice size metering gas to the burners is very suspect and, as I discovered, much too large relative to the design capability of the burners for propane.

- Very probable that there is an issue with delivery pressure. A “lazy” flame indicates the pressure needs to be checked and corrected if inadequate. A system firing on propane should have 11.00 inches water column (W.C.) downstream of the regulator and available at the burner orifice(s). It is difficult to see from the picture, but the gas delivery system to the orifices was almost serpentine in configuration; tubing everywhere! The tubing was 0.25 inch in diameter with each of the four burners orificed to fire 50,000 Btu/Hr. This was truly a “master blaster” but with a gas delivery system very suspect relative to pressure losses. Please remember—pressure losses in a gas delivery system are the enemy and are to be avoided at all costs.

- In looking at the “superstructure” of the burner system, there is a real issue with misalignment of the burners during movement of the trailer. The burners can become displaced, thereby creating a hazardous condition. This definitely needs to be corrected to provide additional stability of the entire system.

- This last point is somewhat academic, but the designer did not consult any design standard prior to initiating the project. It was all “off-the cuff”. Cut and try. If it works fine, if not fix it. No real attempt at obtaining the ANSI standard for gas-fired grills or gas-fired products and following that standard.

Believe it or not, there were corrections made to the design and much better performance did result. That product is now is in the “field test” phase and will be introduced in late summer—ready for kickoff.

BASIC CONFIGURATION:

Now let us examine the basic operation of an atmospheric gas burner. We do so by looking at a typical atmospheric the gas burner design shown as follows:.

BASIC BURENR OPERATION:

Gas is supplied to the burner orifice by virtue of pressure from the distribution system or the gas bottle; i.e.; propane or butane. For natural gas, that pressure is generally delivered between 9.00 and 12.00 inches water column. The gas is then regulated to a delivery pressure between 3.5 and 4.00 inches W.C for natural gas. If the gas is propane or butane, the delivery pressure will be between 10.5 and 11.00 inches W.C. A regulator is located on the gas bottle so adjustments may be made to achieve the proper delivery pressure. It is not uncommon to have an additional regulator mounted on the gas-fired device. All regulators have “pressure ports” from which the gas pressure may be measured so if there is any doubt about delivery pressure, please check. A simple “U” tube manometer is completely adequate for this measurement. Simply measure the difference between the heights of the columns. This difference is the pressure relative to atmospheric.

As mentioned earlier, the air for combustion is called primary air and is provided at atmospheric pressures from outside the appliance. Gas is metered by virtue of the burner orifice. Primary air is drawn through the air shutter as the gas is “streamed” from the orifice opening. The injection of the gas creates a negative pressure relative to the ambient pressure so atmospheric air is entrained through the air shutter and the mixing face. The orifice diameter controls the gas flow rate, generally measured in Ft³/ min or Ft³/Hr. The combination of gas and air occurs in the mixing zone or burner tube. It is very important that the internal design and length of the mixing tube allow for proper combination so a homogeneous gas /air mixture can result and be delivered to the burner head prior to ejection through the burner ports. The venture “throat” serves as a converging / diverging nozzle to increase the velocity of the gas/air mixture prior to entering the mixing tube. The mixture is then swept into the burner head and distributed to the individual burner ports for ignition. The ports act as a restriction to flow; thus, port loading has a great effect on primary air injection. (I would again direct your attention to the glossary in the appendix for the definition of port loading.) It is also important to note that internal burner roughness has an effect on the injection of primary air through friction losses. It is definitely possible to increase primary air by enlarging the burner ports, thereby reducing individual port loading. When this occurs, care must be taken to make sure that no flashback results. Flashback occurs when the velocity of the ejected gas/air mixture is less than the velocity of the flame front through the individual ports. When this occurs, burning may actually “flash back” to the burner orifice. This condition is prohibited by ANSI (The American National Standards Institute). Ignition takes place at one port with carryover to the remaining ports. Again, ignition time should be at or less than four (4) seconds to preclude an accumulation of uncombusted gas. This time is also prescribed by ANSI. Continued ignition takes place around or along the burner ports until gas is no longer supplied to the burner. This control is generally accomplished by virtue of a thermostat that senses temperature or closure of a gas valve done manually by the user.

I definitely hope this very short explanation will help AND provide needed information relative to safety that must be considered when operating heating systems.

CNG/BIO-FUELS

March 20, 2014

The following slides were taken from a post by Charles Murray-Senior Technical Editor, Electronics & Test. The text and commentary are mine.

Compressed natural gas (CNG) has been a possible alternate fuel for quite some time. Natural gas is basically methane in varying percentages due to geographical considerations and constituents found in the “mix”. The heating value ranges between 900 and 1200 Btus/Ft³ with a nominal octane rating of 130. One gasoline gallon equivalent (GGE) of natural gas is 126.67 cubic feet (3.587 m) at standard conditions. GEG is the amount of alternative fuel it takes to equal the energy content of one liquid gallon of gasoline. GGE allows consumers to compare the energy content of competing fuels against a commonly known fuel—gasoline. GGE also compares gasoline to fuels sold as a gas (Natural Gas, Propane, and Hydrogen) and electricity.

This volume of natural gas has the same energy content as one US gallon of gasoline (based on lower heating values: 900 BTU/cu ft of natural gas and 115,000 BTU/gal of gasoline). One GGE of CNG pressurized at 2,400 psi (17 MPa) is 0.77 cubic foot (21.8 liters). Again, this volume of CNG at 2,400 psi has the same energy content as one US gallon of gasoline (based on lower heating values: 148,144 BTU/cu ft of CNG and 115,000 BTU/gal of gasoline. Using Boyle’s Law, the equivalent GGE at 3,600 psi (25 MPa) is 0.51 cubic foot (14.4 L or 3.82 actual US gal).

The National Conference of Weights & Measurements (NCWM) has developed a standard unit of measurement for compressed natural gas, defined in the NIST Handbook 44 Appendix D as follows: “1 Gasoline [US] gallon equivalent (GGE) means 2.567 kg (5.660 lb) of natural gas.”

When consumers refuel their CNG vehicles in the USA, the CNG is usually measured and sold in GGE units. This is fairly helpful as a comparison to gallons of gasoline. These facts make it an ideal alternate fuel due to minimal changes and modifications being necessary for automotive engines. When you throw in the bio-fuel option producing a hybrid vehicle, you have a winning combination. This eliminates problems with infrastructure not providing stations for filling CNG tanks in a judicious manner. Let’s take a look at several vehicles to see the status of CNG/Bio-fuel development.

As you can see, the automotive industry is definitely “on-board” with alternative energy and CNG is one compressed gas they are banking on for the future. We will see commercial entry for these models in the very near future. It will be very interesting to see how they are accepted by the marketplace. I welcome your thoughts. Many thanks.

Share this:

Tagged: Carbon Credits and Allowances, Commentary, Energy, Mechanical Engineering